Description

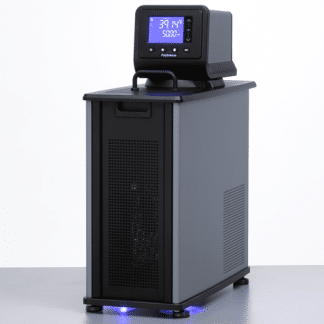

June Company specializes in the technical repair and refurbishment of the WIKA CTB9400 Calibration Bath Repair. This adaptable tool is essential for calibrating temperature probes across diverse environments, from laboratories to workshops. With a temperature range spanning from 28–300°C (82.4–572°F), a user-friendly 5.7-inch color touchscreen, and versatile connectivity options including two USB ports, ethernet, and an RS-232 interface, it ensures seamless operation and efficient data transfer. Clients can rely on our technical prowess for WIKA CTB9400 Calibration Bath Repair through our Service Request Inquiry Form, guaranteeing peak performance of their systems.

Reviews

There are no reviews yet.