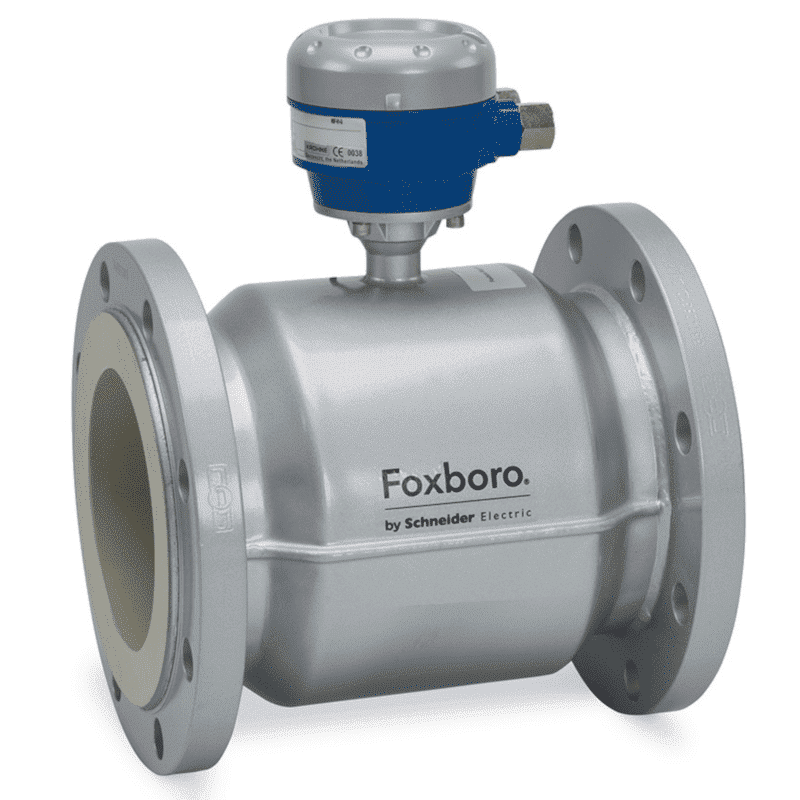

Description

Common Foxboro Flowmeter Issues We Fix:

- Inaccurate Flow Readings – Fluctuating or incorrect measurements.

- Sensor & Electrode Failures – Loss of signal or erratic readings.

- Display & Communication Errors – Issues with HART, Modbus, or Profibus protocols.

- Calibration Drift – Ensuring long-term accuracy and regulatory compliance.

- Power & Wiring Faults – Electrical failures affecting meter performance.

Our Foxboro Flowmeter Repair Services:

✔ Full Diagnostic Testing – Identifying issues with advanced troubleshooting.

✔ Certified Calibration & Verification – Ensuring precision and compliance.

✔ Component Replacement & Repairs – Using genuine Foxboro parts.

✔ Firmware Updates & System Configuration – Restoring optimal performance.

✔ Preventive Maintenance Plans – Extending the lifespan of your flowmeter.

Why Choose My Foxboro Flowmeter Repair Services?

✅ Specialized in Foxboro Flow Meters – Expertise in a wide range of Foxboro models.

✅ Fast Turnaround Time – Minimize downtime with rapid diagnostics and repairs.

✅ Industry Compliance – Calibration meets ISO, AWWA, and regulatory standards.

✅ On-Site & In-House Repairs – Flexible service options to meet your needs.

✅ Detailed Calibration Reports – Certification for compliance and quality assurance.

Frequently Asked Questions (FAQ)

Q: How often should a Foxboro flowmeter be calibrated?

A: Calibration frequency depends on application demands, but annual calibration is recommended.

Q: Can you repair both magnetic and Coriolis Foxboro flowmeters?

A: Yes, I service all types of Foxboro flowmeters, including electromagnetic, Coriolis, and vortex models.

Q: Do you provide calibration certificates?

A: Yes, all calibrations include detailed reports and certificates for compliance records.

Reviews

There are no reviews yet.